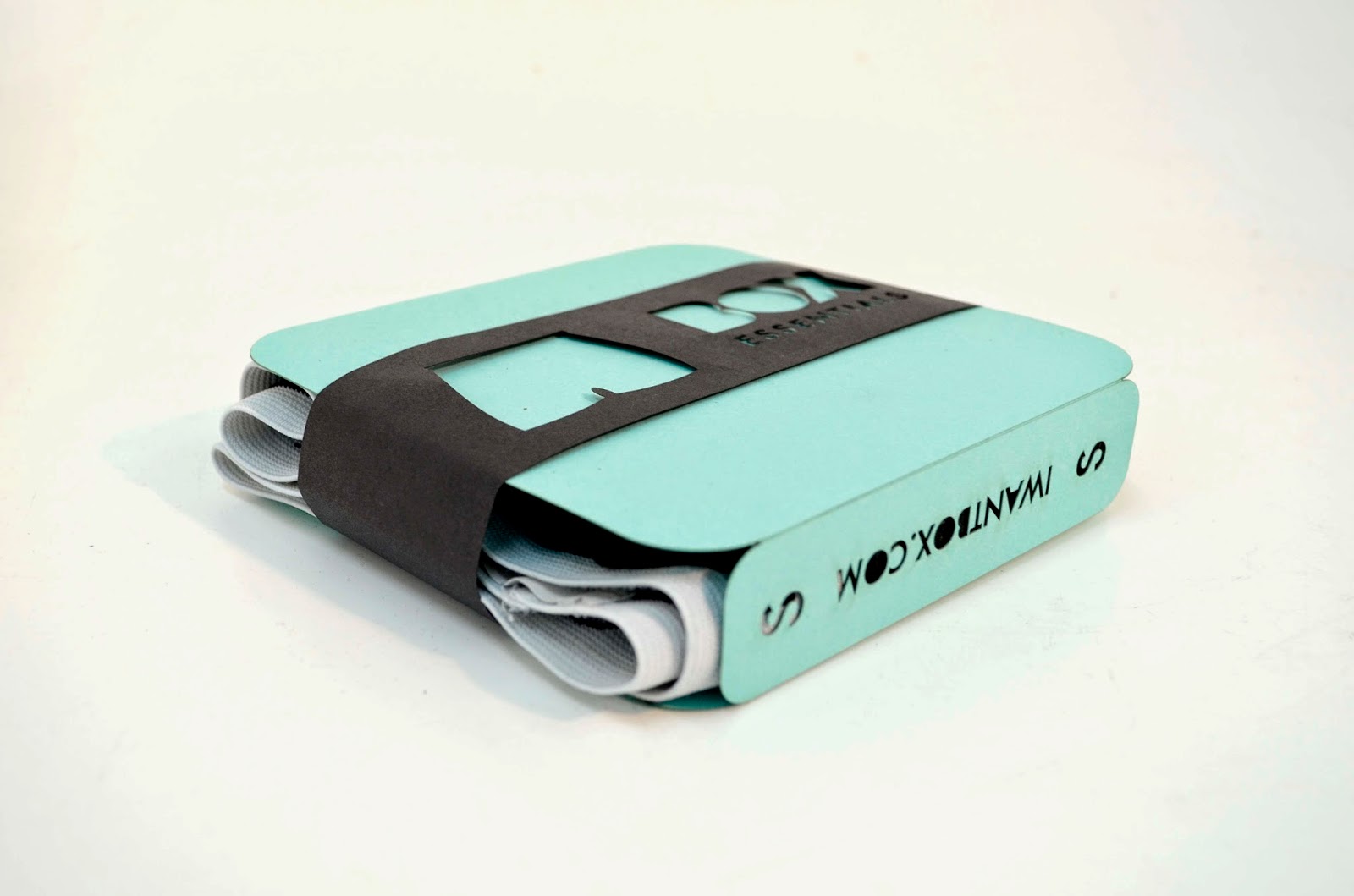

After setting up my template in the required format for the laser cutter , just an hour later my nets came off the press. I chose to use Yellow and turqoise card 200gsm as it was thick

and durable. However if I had more time I would have liked to have sourced something abit more glossy or a matt finish to give it that extra touch and sense of feel when the customer opens it.

I was somewhat happy with the detail of the laser cut , the net fit together perfectly and I really liked the shape. However the laser cutter seemed to have left burn marks around the type and on the strip around the brief shape. This might have been due to the card I used , I was told that it is hard to avoid these burns and the only other way would be to manually scalpel the lettering out . I felt this option would have been time consuming and that I wouldnt achieve near the amount of accuracy than the laser cutter.

I was really happy with how the brief shape turned out on the strip. However again the quality of paper I used wasn't exactly what I wanted. I found the strip to be a little bit flimsy and not thick enough. I still persisted with putting my box together as time was ticking and I was overall happy with the way it looked.

If I had more time I would have liked to have sourced , tested and trailed a lot more materials . As in industry you will have a strict deadline that needs to be met which leaves no room for mistake and the idea process I have undergone . On the other hand this is just a prototype and there to show you how it will work and the functionality but also how it looks physically.

No comments:

Post a Comment